the core of our corporate values

What Are the Stages of the Development of Vascular Stents?

The past development of vascular stents has mainly gone through three stages: bare metal stents (BMS), drug-eluting stents (DES) and degradable stents (BRS); drug-eluting stents are mainly to solve the problem of restenosis after stent implantation DES, but another problem that comes with it is the "late thrombus" that occurs after long-term stent implantation, which is thought to be related to the degradation of the drug carrier on the stent. Therefore, degradable scaffolds with both excellent properties are recognized as the next-generation mainstream scaffolds.

Ⅰ. The development stage of vascular stent:

(1) Bare metal stent (BMS)

Implanted into the human body, it is easy to induce adverse reactions such as thrombosis and endothelial hyperplasia, resulting in intravascular restenosis.

1. Materials used: stainless steel, nickel-titanium alloy and cobalt-chromium alloy;

2. Whether it exists permanently: exists permanently;

3. Whether the coating exists permanently: no coating;

4. Medication time: lifelong medication;

5. The incidence of stent thrombosis: high;

6. Whether it affects blood vessels: influence;

7. Arterial restenosis rate: 20%-30%;

8. Whether it affects the later surgery: Influence.

(2) Drug-eluting stents (DES)

The surface of the metal stent is coated with a drug-carrying polymer coating, which can effectively reduce the restenosis rate, and the long-term safety risks are not known; it can be divided into non-degradable carrier/degradable drug stent.

1. Materials used: The materials of metal stents are mainly 316L stainless steel, nickel titanium alloy (Nickel titanium, NiTi), L605 cobalt chromium alloy (Cobaltchromium, CoCr), etc.;

2. Whether it exists permanently: exists permanently;

3. Whether the coating is permanent: carrier non-degradable drug stent: permanent coating; carrier degradable drug stent: degradable coating;

4. Medication time: lifelong medication;

5. The incidence of stent thrombosis: carrier non-degradable drug stent: low; carrier degradable drug stent: low;

6. Whether it affects blood vessels: influence;

7. Arterial restenosis rate: carrier non-degradable drug stent: 5%-10%; carrier degradable drug stent: <3%.

8. Whether it affects the later surgery: Influence.

(3) Degradable stent (BRS)

When the drug is released to the diseased vascular area, it also dissolves itself, and the stent disappears completely after the vascular lumen reconstruction process is completed; it is divided into degradable polymer/metal stent.

1. Materials used: high molecular polymer, alloy metal;

2. Whether it exists permanently: degradation after a period of time;

3. Whether the coating exists permanently: degradable;

4. Medication time: medication during implantation;

5. The incidence of stent thrombosis: low;

6. Whether it affects blood vessels: no effect;

7. Arterial restenosis rate: very low;

8. Whether it affects the later surgery: no effect.

At present, researchers are engaged in the research and development of the third generation of vascular stents, degradable stents, mainly focusing on degradable polymer stents represented by polylactic acid and degradable metal stents represented by magnesium alloys.

There are three main manufacturing technologies: ① laser engraving technology (widely used), ② 3D precision rapid manufacturing technology (great potential), ③ weaving technology.

Ⅱ. Degradable vascular stent

(1) Polymer fully degradable scaffold (BPVS)

1. Materials used: polylactic acid (PLA), polyglycolic acid/polylactic acid copolymer (PLGA), polycarbonate (PC), polycaprolactone (PCL), polyhydroxybutyric acid (PHBV), polyacetylglutamine Acid (PAGA), polyorthoester (POE), etc.;

2. Material characteristics: Its degradation behavior is related to molecular weight, monomer type, side branch group, etc. The degradation time can be adjusted, but there are problems such as insufficient supporting capacity, thick stent wall thickness, poor blood vessel adhesion, and slow degradation time.

(2) Metal fully degradable stent (BMAS)

1. Materials used: magnesium alloys, iron alloys and zinc alloys are mainly used, and magnesium alloys are the most widely used;

2. Material characteristics: magnesium alloy biodegradation rate is too fast and uneven, good biocompatibility, mechanical properties, mechanical properties are far superior to degradable polymer materials, and can be absorbed by the human body under corrosion; ferroalloy degradation rate is too slow (> 2 years), there are product accumulation problems, etc.; zinc alloy has more suitable degradation rate, degradation behavior and buckling strength, good elongation and better biocompatibility;

3. Surface coating technology: (medical magnesium alloy) micro-arc oxidation, electrodeposition, vapor deposition, polymer, chemical conversion, etc.

Due to its poor mechanical properties, the polymer fully degradable stent has insufficient radial support force compared with the metal stent of the same size. To achieve the same radial support force, the thickness of the stent is much larger than that of the metal stent, reducing the cost of the stent. The effective area of the lumen greatly reduces the indication range of the polymer fully degradable stent. Compared with polymer vascular stents, metal fully degradable stents have better mechanical properties and a slightly faster degradation rate, with increasingly prominent advantages.

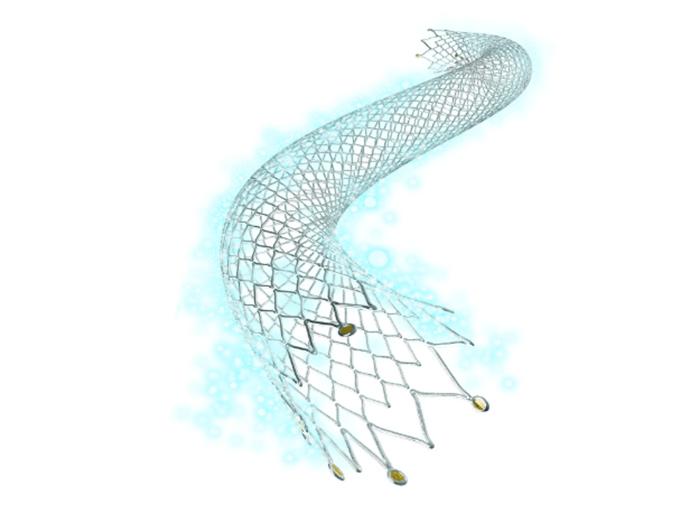

As one of the professional peripheral vascular device companies in China, Zylox-Tonbridge provides varied vascular stents for different patients, including our Zenflex drug-eluting stent and peripheral stent. Feel free to contact us for further info!